Dave Shave, President of Middleby Marshall, highlights the latest technologies, products, and platforms from the world leader in conveyor oven cooking.

PERFECTION AT EVERY PASS

Middleby Marshall is one of the flagship brands of Middleby, a world leader in commercial and residential kitchen equipment and industrial food processing solutions.

“We have spent over 130 years perfecting the bakery conveyor oven cooking process to enable restaurants to provide excellent, consistent food and superior service to customers,” opens Dave Shave, President of Middleby Marshall.

A highly respected and well-recognized brand in conveyor oven technology, Middleby Marshall proudly manufactures conveyor ovens and continues to pursue innovation in automated cooking solutions.

Indeed, its combination of different conveyor technologies allows restaurants to become automated, enabling guests to be served faster while reducing labor costs and delivering high-quality dining experiences to customers.

“We have always been at the forefront of incorporating new technologies that allow our customers to prepare orders faster and more consistently with less expense and manpower,” says Shave.

One such technology is air impingement, which enables the Middleby Marshall conveyor oven to bake products more quickly than deck ovens, thereby increasing output.

Impingement allows air to move rapidly through a tunnel of heat; multiple oven sizes and energy options are available depending on customer requirements.

“Energy management is important so customers can save costs by reducing their energy usage. While the oven may not be busy all times of the day, it needs to remain on. Our innovation helps operators cut energy usage when the oven is idle between more active periods,” Shave explains.

“During this idle rate, the main air impingement blowers slow down the amount of air being forced through the oven and allow the burner to operate more efficiently, reducing fuel consumption and, in turn, operator costs.”

Alongside air impingement, Middleby Marshall utilizes long-wave infrared conveyor oven technology, leveraging the same tunnel design and opening up an entirely new range of menu options and benefits for the industry.

“Our customer base has always been and continues to be the pizza industry, but with this range of product platforms and our focus on the tunnel of heat, we have expanded to casual dining, stadiums, healthcare, education, and other markets,” outlines Shave.

“I was honored to be named President of Middleby Marshall last year. My priority is moving this prestigious company forward, bringing new innovations and benefits to what is an amazing industry.”

LONGWAVE LAUNCH

In the casual dining sector, the CTX brand has been a world leader in long-wave infrared conveyor oven technology and part of the Middleby Marshall portfolio for the past 15 years.

However, the company recognized the need to revisit the technology and provide a number of enhancements.

As a result, Middleby Marshall has introduced its all-new LongWave ovens designed to streamline kitchen operations, reduce the reliance on manual labor, and lower operational costs.

“We are focused on vertical cooking with the ability to stack the LongWave, increasing throughput. Think of LongWave as your automated chargriller,” Shave says.

The first enhancement was to increase the maximum temperature of LongWave ovens to 1,200 degrees Fahrenheit.

Then, investments were made into connectivity so LongWave ovens can connect to Open Kitchen, the only Internet of Things (IoT)-based solution that combines equipment monitoring, facility performance, and food safety.

“This allows for key components of the ovens to be monitored and channel data back for service and operations,” says Shave.

“What we observed with CTX was that there was no relay back to operations if the self-cleaning function had been activated. With IoT on LongWave, reporting can be sent to operations to ensure the cleaning frequency by staff has been adhered to.”

LongWave ovens additionally offer improved environmental operation as Middleby Marshall has redesigned the cooling unit.

This has dramatically lowered the surface temperature of the ovens, thereby creating a cooler working kitchen environment.

Moreover, given that long-wave infrared conveyor oven technology is a game-changer for the industry, education will be key to the success of LongWave.

Middleby Marshall has therefore invested in dedicated culinary expertise to drive the benefits of its LongWave ovens to the industry.

“With the global infrastructure and footprint of Middleby, we can educate, demonstrate, install, support, and gain feedback on LongWave with greater efficiency,” Shave tells us.

INNOVATION AND TRADITION

Alongside LongWave, the company is collaborating with other Middleby brands as it continues its product automation journey.

For example, it has worked with Lab2Fab (L2F) on the Pizza Bot, which accurately dispenses toppings so employees can focus on customers and optimize productivity.

“The Pizza Bot supports the automated building of the pizza and transferring into Middleby Marshall conveyors, including the PS638 ventless ovens, supporting the most productive ventless system in the industry with over 150 pizzas per hour,” acclaims Shave.

“This not only supports labor realignment but puts an increased focus on reducing capital expenditure (CapEx) costs for the operator.

“Customers are still looking for the highest level of technology, connectivity, and energy efficiency, but there is also a need for a product line-up that benefits from a CapEx standpoint as the pressure on store build costs continues.”

While some customers readily accept innovative technologies and want to incorporate them as soon as they are available, others prefer to stick to traditional methods.

In either case, Middleby Marshall is there to support customers, as evidenced by its PS540 and PS3240 series of ovens which incorporate traditional-style controls.

The PS640 series, meanwhile, features OneTouch, a high-resolution user interface that allows the operator to set up to 15 presets, each containing the bake time and temperature as well as a picture of the product being cooked.

“Operators can change from one preset program to another by simply selecting a new preset, and the oven will automatically adjust the bake time and temperature to the new settings,” Shave insights.

“OneTouch can also be operated in manual mode, which is like older ovens in that the operator sets the bake time and temperature independently.”

Additionally, it includes lockout features that prevent accidental setting changes, IoT functions, and internet connectivity for remote monitoring.

“Ovens with OneTouch also have energy-saving features incorporated into them,” adds Shave.

“We are working on the next line-up of products and supplementary enhancements to provide various benefits to the industry. Watch this space for more exciting developments!”

Dave Shave, President, Middleby Marshall

ENHANCED PRODUCTS

Over the past few months, using industry feedback and working closely with its production and engineering teams, Middleby Marshall now has a clear path for its product platforms.

Popular models such as the PS520 and PS540 have been brought back, while other items that didn’t fit various markets or the needs of the business have been removed.

“Our PS platforms have been the staple for the pizza industry for many years. We continue to review them and drive efficiency and performance with these models,” Shave sets out.

Elsewhere, Middleby Marshall has expanded its X-Series range with the introduction of the X55 and X70, which have enhanced features to improve speed of operation and save energy, along with the launch of the X20 and X26, providing throughput options for businesses of any size.

“We are working on the next line-up of products and supplementary enhancements to provide various benefits to the industry. Watch this space for more exciting developments!”

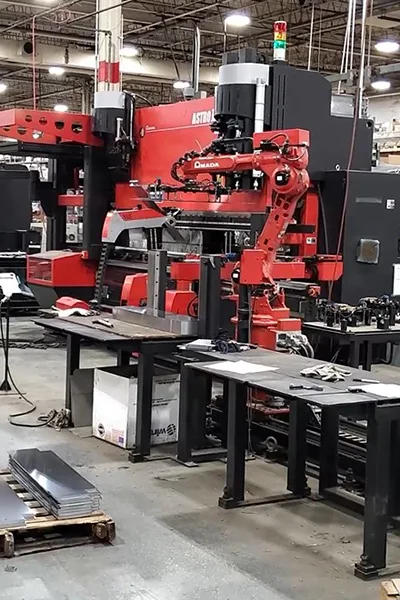

There has equally been considerable investment in manufacturing technologies at Middleby Marshall’s 170,000 square foot facility in Elgin, Illinois which can produce all models quickly and efficiently.

For example, the company continues to invest in processes within its manufacturing facility to deliver on its promise of high-quality products that stand the test of time.

As such, in the face of global challenges, Middleby Marshall in many ways controls its own destiny to support customer needs.

“We all know the industry has faced challenges over the past few years with the supply chain, labor, and rising food costs to name a few, but this is where Middleby Marshall and Middleby overall is well positioned to drive forward,” affirms Shave.

The company also works in tandem with some international Middleby-owned manufacturing facilities in China and the Philippines where specific models are produced for Asia-based customers, enabling efficiencies to be passed onto them.

This means that Middleby Marshall is well-positioned to bring profitable solutions to the industry and provide support not just in North America, but across the world.

“With these facilities, we have been able to create focus and collaboration with other areas of the business, such as our engineering, service, and sales departments, effectively creating a business that operates 24 hours a day,” Shave explains.

EXCITING PROSPECTS

This 24-hour operation is one of several Middleby Marshall targets for 2025, with another key priority being its international distribution and sales focus.

“Middleby has unmatched infrastructure in the conveyor space, and we have already set upon a focused strategy with this support,” reveals Shave.

“Our approach is simple – create an exemplary experience for our customers at every step of the process and make Middleby Marshall the easiest to do business with in the industry.”

It is also set to continue leveraging data across every area of the business, from sales and service to manufacturing and distribution, to drive efficiencies, having made significant strides in this regard last year.

Last but not least, the growth of LongWave is a major goal for Middleby Marshall, with a focused marketing and strategic selling plan in place for the game-changing platform.

“I am excited about 2025 and beyond, positioning Middleby Marshall for remarkable things,” closes Shave.

“We have the greatest depth in product knowledge of conveyors and developed a culture where we strive for perfection within every area of the business. This has led to our new branding – Perfection at Every Pass.”